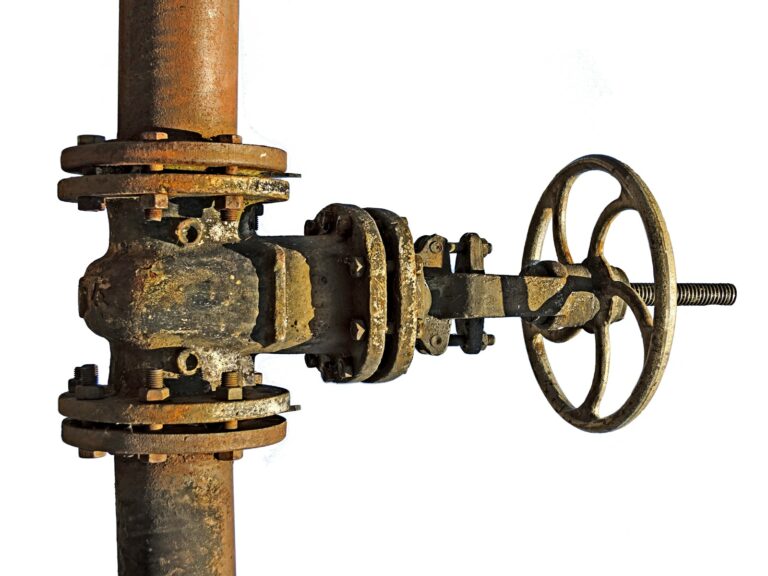

Contrary to popular belief, old age is not responsible for many pipe failures. Instead, a failure to prevent and control corrosion is at fault. Galvanic corrosion is one of the most common types of corrosion. Water mains in particular suffer from this problem. We often hear from homeowners asking what is galvanic corrosion, what are the primary causes of galvanic corrosion and how we prevent galvanic corrosion in our pipes?

What is galvanic corrosion?

So what exactly is galvanic corrosion and how does it effect my pipes and metal in general?

“For a galvanic cell to form, two electrochemically different metals must exist within a localized electrolytic environment.”

What does that mean for your home? Well, if you have the proper conditions, galvanic corrosion can have devastating effects on your pipes. This problem occurs when two different metals both share an environment that contains an electrolyte. These examples demonstrate just how massive this problem can become.

Just like the electrolytes in a sports drink help fluids move throughout our bodies, the electrolytes in the pipe’s environment allow ions to move from one metal to another. This means that one of those metals is going to get stronger – at the expense of the other.

This insidious damage is not necessarily visible, either. As corrosion engineer Jim Lary explains:

“Older cast iron pipe consists of flakes of graphite (carbon) in an iron matrix. When the metal corrodes, it loses the iron constituent, leaving behind the graphite. Pipe that has turned to graphite often retains the appearance of sound pipe, leading casual observers to mistakenly believe the pipe has remained corrosion-free…”

Pipes that look fine on the outside, may not be fine on the inside. That is why you need an experienced plumber to inspect your home’s pipes if you suspect a problem! Fortunately, our plumbers at Balkan have the experience to recognize galvanic corrosion, and they also know how to correct it.

The primary causes of galvanic corrosion

There are three main causes of galvanic corrosion; direct current being transferred onto to a water service line from the secondary electrical ground. Dissimilar metals are connected to each other, such as galvanized pipe and copper tubing. Lastly, stray electric current running underground from damaged or defective underground utilities. Each of these causes has particular factors and must be mitigated individually.

Three ways to prevent galvanic corrosion

For each of the above three causes of galvanic corrosion, there are corresponding solutions and preventive measures that can be taken. What follows are three recognized means to prevent pipe damage from galvanic action, or electrolysis:

1. Grounding rods instead of grounding to a water line

The purpose of a secondary electrical ground is to protect household electrical appliances and systems from thunder strikes, accidental contact with higher voltage systems, or the failure of the main ground that is connected to the electrical panel. But electrical grounds connected to your water service line are also the cause of galvanic corrosion in many cases.

A viable option to prevent galvanic corrosion, and electrolysis on your water service line, is to replace the ground wire connection to your water line. More frequently household electrical systems are using grounding rods instead of grounding to the water service line. As a matter of fact, the National Electrical Code (NEC) now recommends supplementing grounding to the cold water service line with a grounding rod. It is highly recommended that the installation of a grounding rod be done by a licensed electrician.

Typically 8’ of the grounding rod must extend into the ground. The materials used for a grounding rod can vary. Copper-coated rods are commonly used, as copper prevents corrosion from being in contact with the ground. But galvanized rods may be a better choice. It is suggested a licensed electrician perform the installation. A sending pit may have to be dug to ease installation and help prevent injury during the installation. In many cases, it is very difficult to install an 8′ grounding rod from atop a basement floor.

Modern solid-state appliances can send direct current through the electrical ground, and through the cold water service line. Direct current can destroy copper water lines in less than 2 years. Grounding rods have been in use since the advent of electricity, and Benjamin Franklin’s time, so they have a long history of successful use. Grounding rods have a general life expectancy of 15 years.

2. Dielectric couplings prevent galvanic corrosion

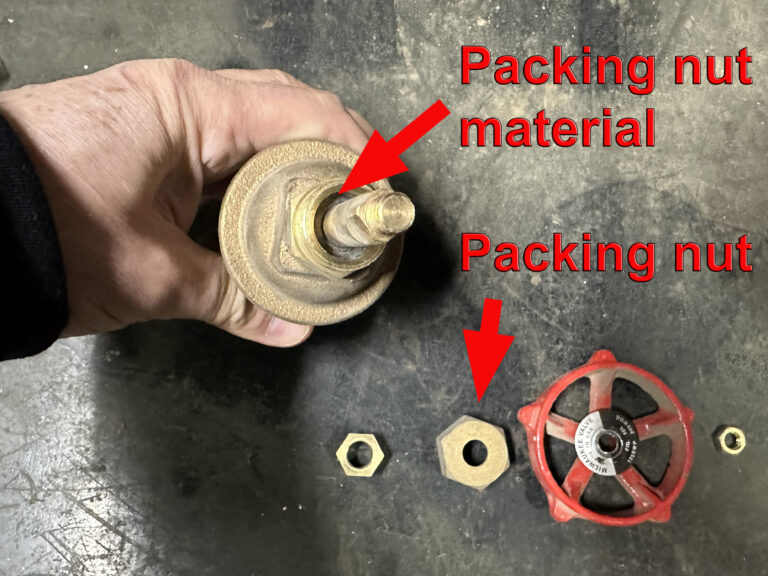

Dissimilar metals conduct electricity at different rates. The connecting points of two different pipe materials become rotted by galvanic corrosion in a relatively short period of time. A prime example of this is when galvanized pipe is connected to copper or brass. Ideally, the old galvanized pipe should be replaced. However, the expense, or sensitive area of the piping, may make pipe replacement undesirable. In those cases, a dielectric coupling can be used.

A dielectric coupling is easily installed between the two dissimilar metals. Unlike other plumbing fittings, it has a rubber ring gasket that stops the flow of electricity between the two metals. it is advised to check your local plumbing code to ensure such fittings are legal. Dielectric couplings are not particularly expensive.

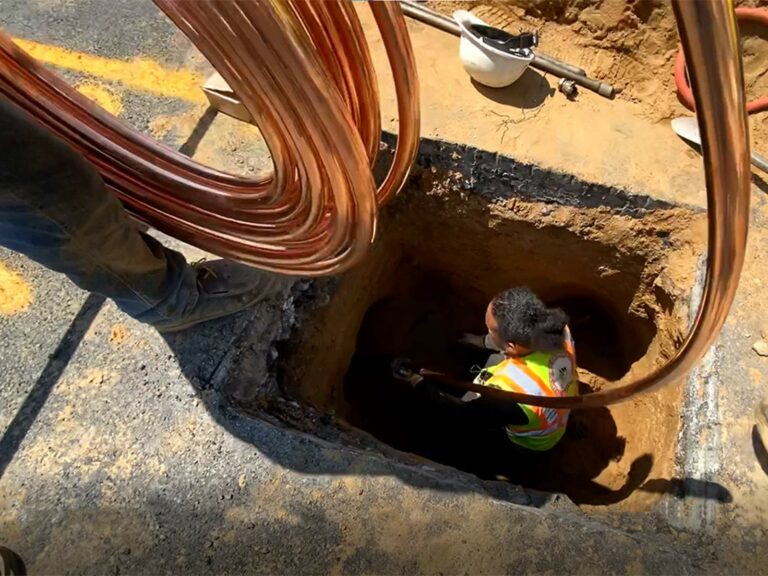

3. Wrapping water lines in plastic prevents galvanic corrosion

Bare copper or brass water lines are great conductors of electricity. Therefore they are prone to electrolysis and galvanic corrosion. Similar to electric wires being coated with rubber or plastic, water lines can be protected in the same way. If underground water lines are installed inside plastic or rubber tubing, stray electric current cannot reach them. If left unprotected, underground copper or brass lines can be rotted out by galvanic corrosion in two years or less. Water main contractors typically use to cover copper water lines are PVC, or plastic irrigation tubing.

Contact Balkan Sewer And Water Main Service for all of your plumbing needs or to take advantage of our free, no-obligation inspections.