Soldering copper pipe is more commonly known as sweating pipe. In terms of degree of difficulty, it is mid-range. Not the simplest thing to do, but far from the most difficult plumbing task. The first question to ask yourself is, what is your skill level. You will be directly involved in the drinking supply for you and your family, and for a plumbing installation that should last decades. Take that all into account while deciding to hire a plumber, or undertaking this task yourself.

Like any plumbing task, you need to know what items are required, and have an orderly process to complete it. This article will set you on the right path to a successful and long-lasting plumbing installation. We will also give you some valuable safety tips.

Soldering Copper Pipe: Your 11 Item Checklist

- Work gloves so you do not get burned (safety 1st at all times)

- L Type copper tubing (also called sweat pipe)

- A 14.1 oz. tank of MAPP gas with a self-lighting torch head

- Striker to light the torch if your torch is not self-lighting

- Copper tubing cutter

- Abrasive pad and wire brush to clean off copper tubing and fittings

- Flux to burn impurities off of copper before you start soldering it

- Lead free solder

- Heat shield to protect flammable articles from burning (wood beams, sheet rock, etc.)

- Small container of water and a small towel to cool off heated pipe (never touch freshly soldered pipes)

- Measuring tape to measure tubing before cutting it

A successful process for Soldering Copper Pipe

Like any plumbing or household job, a set process ensures success. The first step is assembling all of the needed items for soldering copper pipe, as stated above. What follows is a sensible approach for leak free and long lasting water supply lines.

Your 10 part path to a successful soldering job

- Cut and pre-fabricate as much of the installation as you can. That also means installing pipe hangers or supports as needed.

- Clean and add flux to all contact points before you join them.

- Before soldering copper pipe begins, leave an outlet for moisture to escape.

- Install branch line valves at every riser, or before every plumbing fixture branch line.

- Place a heat shield between every flammable object and your torch.

- Start from the lowest point, and heat the joint.

- Your torch should be placed at a point where the flame surrounds the joint. Always apply the heat to the fitting itself (coupling, union, elbow, etc.), not the copper tubing.

- If pressure will be applied on the newly soldered copper pipe joint, cool it with a wet rag to solidify the joint.

- After all joints have been soldered, open an outlet on a higher floor, or higher elevation. Open the water to it extremely slowly.

- If you see a leak, it is important to remember to have a way for the water in the pipe to escape. You will never fix a leaky joint until the water inside your water line has a way to escape.

3 Extra helpful installation and safety tips:

1. Always solder from the lowest point to the highest point – heat rises. You will be pre-heating the next solder joint, and expediting your job.

2. If water or moisture is trapped inside the pipes your soldering will not hold. Water, or any moisture, needs an outlet. You just need to have an open union, open valve, or any outlet for moisture to escape.

3. Never “super heat” a section of pipe with water trapped inside of it. Heated water can turn to steam, and burst the pipe. Once steam bursts out of a pipe it can cause severe burns.

Some things You can do and some things not

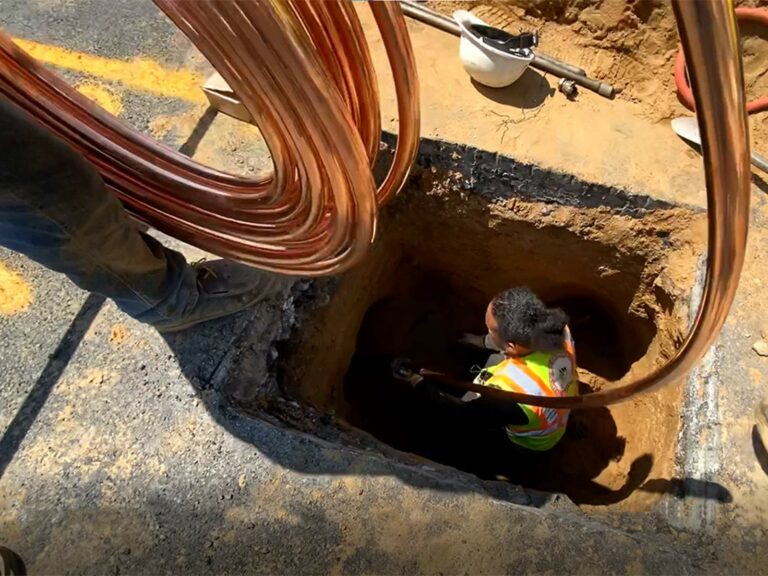

While soldering copper pipe may fall into the category of a “do-able” task for a skilled property owner, other plumbing tasks do not. Among the things on the DIY not to do list are house sewer and water service line repairs and replacements. If you live within the confines of NYC or Nassau County, trust the company that more New Yorkers have trusted than any other for over 65 years. That company is Balkan Sewer And Water Main Service.

Balkan was founded in 1952, and through its team-wide commitment to customer service, is NYC’s largest house sewer and water service line contractor. Count on expert advice, and professional and courteous service 7 days a week, and after-hours as well. Contact Team Balkan for a free and no-obligation site visit, and expert advice.